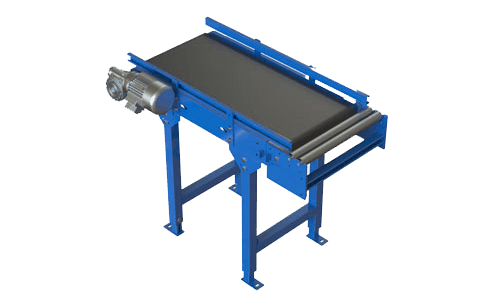

SMD Belt Conveyor

High quality shaft mounted drive belt conveyor. Manufactured to suit your required length & width. Available in stainless steel or mild steel!

High quality shaft mounted drive belt conveyor. Manufactured to suit your required length & width. Available in stainless steel or mild steel!

The SMD Belt Conveyor is a shaft mounted drive belt conveyor, complete with various motor & drive roller sizes. The shaft mounted design offers easy access to the gearbox motor & roller for maintenance. The conveyor helps transport product quickly, safely and with ease. It has a high build quality, perfect for coping with the strains of the factory & warehouse environment.

The belt has a range of different materials and colours to choose from. Popular materials include smooth top and grip top. The drive roller is also available with a rubber lagged finish if required.

The SMD Belt Conveyor comes with series options & accessories some of these include inclined conveyor, horizontal conveyor and Safety pop-out rollers. Various electric controls are available to suit your requirement.

Ocon Conveyors manufacture various belt conveyors, if the SMD Belt Convenor does not suit your requirement please view alternatives. We have the EDD Belt Conveyor, CDU Belt Conveyor & the Mini Belt Conveyor (please find more related products below).

Product comes with 1 year warranty

| Drive Type | Shaft mounted drive unit |

|---|---|

| Drive power options (kW) | 0.37 & 0.55 kW |

| Frame Material | Mild steel or Stainless steel |

| Frame Finish | Mild Steel = Powder coated Stainless Steel = Self colour |

| Frame Detail | Bed depth options = 120mm, 140mm & 142mm |

| Idle Roller Diameter Options | 89mm & 115mm |

| Drive Roller Diameter Options | 115mm & 160mm |

| Belt material options | Smooth top, Grip top & longitudinal – various colour options |

| Minimum standard length | 1,200mm |

| Max standard length | 15,000mm |

| Standard belt width options | 200, 250, 300, 350, 400, 450, 500, 550, 600, 650, 700, 750, 800, 850, 900, 950, 1000, 1050, 1200, 1250, 1300 & 1350mm |

| Series options / accessories | Horizontal conveyor Inclined conveyor Straight modules 30, 45, 60, 90 & 180 degree bends -SMD Safety pop out rollers Various speed options Variable speed control Bespoke electrical control panels Photo electric cells, bar code reading, emergency stops etc Braked motor Rubber lagged drive roller Side guides – fixed & adjustable Lift up access gate (gas assisted) – DRIVE CHANGES TO CDU Fixed support stands Mobile support stands Twin & Multi-Tier Support stands Under guard as standard |

What Belt is used on a horizontal belt conveyor?

Our standard belt for a horizontal belt conveyor is a 2 ply PVC smoothtop belt. Other belts can be offered to suit specific applications

What drive motor is used for this belt conveyor?

A shaft mounted gearbox motor is used for the conveyor design. The drive sits nicely on the side of the conveyor, mounted to the drive roller. Many of our customers like this design as it gives them easy access to the gearbox motor for maintenance

How do you track a belt conveyor?

You track the belt conveyor using our high-quality adjustable tracking rollers. Instructions are available upon request.

Can you change the speed of the belt conveyor?

Yes, when you purchase a variable speed option in conjunction with the conveyor. This enables you to adjust the speed, many different speed ranges are available at quoting stage.

Can you change the speed of the belt conveyor?

Yes, when you purchase a variable speed option in conjunction with the conveyor. This enables you to adjust the speed, many different speed ranges are available at quoting stage.

Can you easily change the belt?

Yes, belt conveyors can be fitted with vulcanised endless a belt or with a mechanical fastener for easy maintence.

Where is the conveyor manufactured?

We are proud to manufacture our conveyors in the UK since 1981. Manufactured in our factory in Aldridge Walsall, with our highly skilled engineers.

We can manufacture bespoke conveyors to suit your requirements.

Westgate House, Westgate, Aldridge, Walsall, England, WS9 8EX

Phone 01922 452 333

Email enquiries@ocon.co.uk