Material handling conveyor systems are an effective tool to transport goods and products within a facility. Reduce foot traffic and streamline operations with the right conveyors for your business.

Easy to Operate, Strong and Versatile

The material handling conveyor can be implemented during production, assembly, inspection, loading and unloading, and packing phases of the operation.

The most common conveyor for material handling is a continuous belt conveyor, but many use rollers, slider pans and other accessories. Powered by electric motors with variable speed controls, these conveyors are easy to operate.

Heavy-duty frames, supports and robust rubber belt materials are available.

Transport Materials Quickly and Efficiently

The transportation of any material across your facility should be handled with care. Your material handling conveyor, and the materials used to construct it, can be customised to your exact needs.

We also provide accessories and ancillary equipment to improve throughput and efficiency.

The Benefits of a Material Handling Conveyor system:

There are many benefits to introducing or incorporating a conveyor belt for material handling into your industrial setting.

These include but are not limited to the following:

Reduce manual handling aspects

Here at Ocon Conveyors, we understand that the safety of your staff is important. Many manual handling roles include the completion of menial, dirty or even dangerous tasks. But with the installation of a material handling conveyor, you can reduce the manual handling aspects of these positions.

With repetitive movements automated, your staff will find greater job satisfaction, with some operatives even able to be reallocated to value-added jobs and/or tasks to enhance your business as a whole. Safety is another factor that will be dramatically improved via the integration of material handling equipment conveyor systems.

Lower operational costs

Keep your operational costs low, whatever the latest industry trends or consumer demands brings, by using a conveyor belt for material handling. Seasonal peaks and periods requiring increased production output can be handled with ease and without adding to staff numbers by relying on this automated solution.

Reduce personnel MHE movements

Thanks to the use of a material handling conveyor, your facility can keep operations as ergonomic as they should be. These improvements will lead to reduced personnel MHE movements and the manual carrying/transportation of goods to keep workers happy, production on track, and product quality high.

Improving production output

A material handling equipment conveyor doesn’t just keep operations running smoothly. Products or materials can be transported with precision at speed to improve production output as a whole. Seasonal demands can also be catered for without increasing costs company-wide. With improved production output, you’ll be better positioned to hit targets and cater to the requirements of your own customer base.

The minimal maintenance required to keep production flowing will also decrease disruptive downtime to improve the entire efficiency of your operation.

Elevation to high level for increased production space/access

Making every inch of your facility work for you is crucial, whatever industry sector you serve. With selected material handling conveyor systems, you can maximise not just floor space but elevate your operation to a higher level. Many material handling equipment conveyor systems can be used vertically or around corners to ensure increased production space and easy, uninhibited access.

Increased efficiencies and accuracies

With a conveyor belt for material handling, your facility can look forward to a long list of increased efficiencies and accuracies at every level. The automation of repetitive movements and reduced personnel walking will keep operations efficient and ergonomic. The intelligent, safe transportation of products means less risk, damage and loss.

Material handling conveyor systems can be integrated seamlessly to ensure fewer disruptions when enhancing the infrastructure you need to support your operation. Modular material handling equipment conveyor systems can also be incorporated to support workstations and specific processes as and when it’s needed.

What type of conveyors are most suitable for Material Handling?

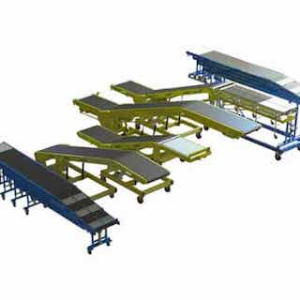

We provide access to conveyors that improve how you process, handle and transport goods and parts. Belt, overhead, modular plastic, gravity, and flexible conveyors can all be integrated into a streamlined material handling system.

Material handling conveyors are versatile equipment. We tailor systems to suit the specific layout of your facility to guarantee improved efficiency and productivity for your organisation, even when processing a high volume of goods.

Powered horizontal and incline belt conveyors in a wide range of sizes, drive configurations and finishes.

Choose smooth belt and grip-top belts for standard material handling requirements, heavy duty conveyor belts, fire retardant and food quality belts. Conveyor belts can use end drives, integral drum drives and variations of centre drives.

Roller or gravity conveyors are simple & cost-effective solution for material handling, no power required. Our Speedtrack range covers all requirements, from mini roller 100 series to heavy-duty 900 series.

Materials include aluminium and stainless steel for general or food grade applications.

Highly mobile, extremely flexible: the Expandaveyor can be moved, stretched out and positioned in minutes. Simply wheel it out and expand it straight or around bends to suit your needs.

We fit flexible conveyors with skatewheels or rollers in plastic or stainless steel, to suit all material handling needs.

Perfect for material handling of mild steel or ferrous parts such as scrap. Horizontal and inclined conveyors are available, with nose over to drop parts into containers.

Vehicle Loading/Unloading Conveyors

Built to extend into containers, lorries and vans for streamlined material handling of deliveries. Mobile conveyors with powered belts and rollers, adjustable heights, inclines and extendable sections.

Driven by belt, chain or spool, powered rollers provide a consistent speed of movement for flat materials, totes, boxes or pallets. Available with mitre and merge sections, access gates and ZLP accumulation properties.