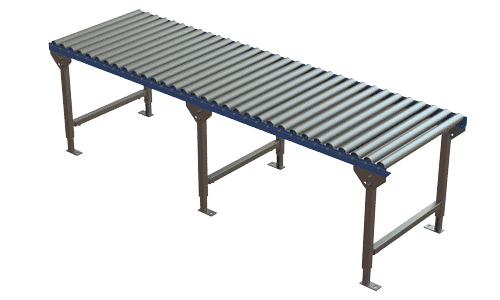

800 Series Gravity Conveyor

Heavy duty steel framed gravity conveyor. Steel roller conveyor, strong and robust!!

Heavy duty steel framed gravity conveyor. Steel roller conveyor, strong and robust!!

The 800 Series Gravity Conveyor is a heavy-duty roller conveyor. Fully welded construction complete with strong rolled steel angle side members make it perfect for a more rugged environment. The rollers are assembled with drilled & wired axles for maximum strength. The conveyor length, width and pitch are manufactured to suit the customer’s specific requirements.

Steel rollers are standard for strength, available in 50mm or 60mm diameter. Rollers are mounted in a mild steel side frame with a powder coated finish. This series comes with many options & accessories including ball tables, lift up access gates, bends, side guides and end stops (find all series options and accessories listed below).

Gravity conveyors are essential in a wide range of industries where it is necessary to transport items from A to B. The 800 series gravity conveyor helps to do this quickly, safely and with ease.

Ocon Conveyors manufacture a large selection of gravity conveyors in its Speedtrack range, if the 800 Series does not suit your requirement please view alternatives. We have eight different options in our gravity conveyor range suit many applications including light, medium and heavy-duty conveyors, find all our related products below.

Product comes with 1 year warranty

| Side Frame Material | Mild steel |

|---|---|

| Side Frame Finish | Powder coated |

| Side Frame Detail | Angle = 50x50x6mm |

| Roller Diameter | 50mm & 60mm options |

| Roller Material | Mild steel zinc plated |

| Roller Pitch | 60, 75, 100, 125, 150 & 200mm options |

| Roller Rating | BZP 50mm= 80kg & BZP 60mm= 120kg |

| Standard Widths | 300, 400, 450, 500, 600, 700, 750, 800, 900 & 1000mm |

| Series options / accessories | Straight modules 45 & 90 degree bends Sideguides Ball platforms / Ball tables Endstop plate Lift up access gate Support stands (various height options) |

What is a roller pitch?

A roller pitch is the distance from the centre of a roller to the centre of the next roller.

What roller pitch do I require?

As a general rule, the base of the box should always cover 3 rollers. For example, a 300mm long product would require a minimum pitch of 100mm (300mm ÷ 3 rollers = 100mm).

What are the advantages of PVC conveyor roller?

Our PVC roller is a free-running, low inertia roller, so is perfect for lightweight products. It is also a more cost-effective conveyor compared to the steel roller

What are the advantages of a steel roller conveyor?

Steels roller are perfect for heavier products as the tube and bearings have a higher capacity rating.

Can you manufacture to suit any length of the conveyor?

Yes, we can manufacture to suit your requirements. However, a length is always divisible by the pitch. For example, a request for 10,000mm at 75mm pitch would be manufactured at 9,975mm long (usually supplied in 3x 3,000mm & 1x 975mm sections)

What are the advantages of skate wheel conveyors?

Skate wheels are extremely free running, so light product can convey with the conveyor set at a small angle. They are also fantastic at tracking product around bends. Another benefit is you can put products side by side & they will run independently. Useful Tip – Flat based products are required when using a skate wheel conveyor.

What slope should I set the gravity conveyor?

The angle a gravity conveyor is set at depends on the number of factors. Three main considerations are the weight of the product, the base of the product and the speed you wish the product to travel. These factors contribute massively to the slope that is should be set at.

We can manufacture bespoke conveyors to suit your requirements.

Westgate House, Westgate, Aldridge, Walsall, England, WS9 8EX

Phone 01922 452 333

Email enquiries@ocon.co.uk